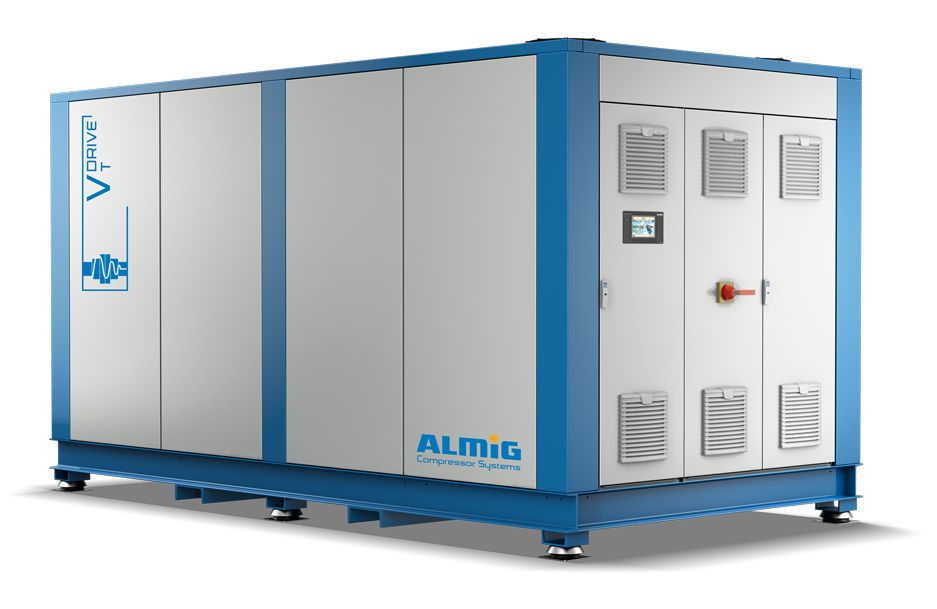

SCREW COMPRESSOR VARIABLE XP

The speed-controlled screw compressors of the VARIABLE XP series are the optimal solution for always providing the right amount of compressed air when the demand for compressed air fluctuates.

Power output in kW

Volume flow according to ISO 1217 (Annex C-2009) in m³/min

Operating pressure in bar

Description

COMPRESSOR SERIES VARIABLE XP

With the integrated frequency converter, the specially designed motor only turns as fast as is necessary to generate the required amount of compressed air. Expensive idle times are thus a thing of the past. The system thus represents the right solution for high cost-effectiveness and an efficient compressed air supply. The product range offers delivery rates of 0.89 – 35 m³/min at operating pressures of 5 – 13 bar. In the development of the new VARIABLE XP screw compressor series, the reliability and service life of the components have been further improved by optimising the cooling air flow. Thanks to additional sound insulation, the unit can also be installed where noise levels are critical.

Market analyses show that compressors are only utilised to approx. 50-70 % on average. However, the maximum delivery volume is only needed at peak times. That is why we have developed the ALMiG SCD technology, whose strength lies in the partial load range – exactly where it is needed.

SCD technology stands for speed control and direct drive as a holistic drive concept with maximum economic efficiency. Energy savings of up to 35 % can be achieved through:

- Speed control

- constant mains pressure, infinitely variable from 5 – 13 bar

- extremely good system efficiency

- no start-up switching current peaks

- no expensive idle times

Technical information

| VARIABLE XP | Volume flow according to ISO 1217 (Annex C-2009)* | Rated motor power |

Length | Width | Height | Weight | |

|---|---|---|---|---|---|---|---|

| Model | min. | max. | kW | mm | mm | mm | kg |

| 22 | 0.89 | 3.90 | 22 | 1250 | 880 | 1515 | 560 |

| 30 | 1.54 | 5.50 | 30 | 1350 | 940 | 1680 | 830 |

| 37 | 1.54 | 6.60 | 37 | 1350 | 940 | 1680 | 855 |

| 45 | 2.98 | 8.38 | 45 | 2000 | 1250 | 1750 | 1555 |

| 55 | 2.98 | 10.48 | 55 | 2000 | 1250 | 1750 | 1640 |

| 75 | 3.83 | 14.48 | 75 | 2180 | 1330 | 1850 | 2025 |

| 90 | 3.83 | 16.93 | 90 | 2180 | 1330 | 1850 | 2120 |

| 110 | 6.50 | 21.00 | 110 | 2940 | 1710 | 1825 | 3000 |

| 132 | 9.92 | 25.20 | 132 | 2940 | 1710 | 1825 | 3500 |

| 160 | 9.92 | 29.20 | 160 | 3300 | 1860 | 2145 | 3700 |

| 200 | 9.92 | 35.00 | 200 | 3300 | 1860 | 2145 | 3750 |

* based on an operating overpressure of 7 bar at 50 Hz

Application industries

Application industries

Automotive industry

Metal industry

Quality characteristics